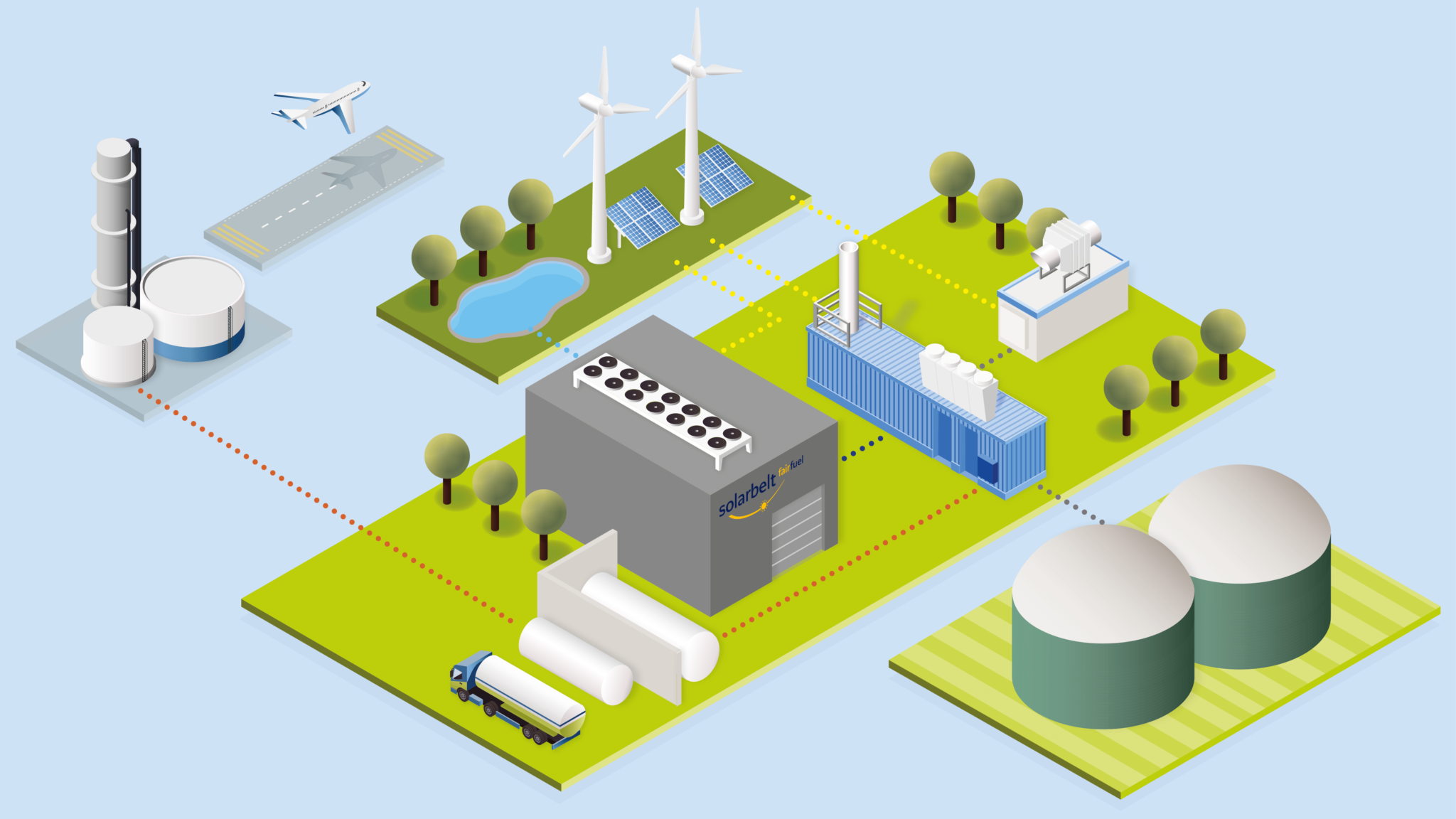

Overview of the Plant in Werlte

Electricity from renewable sources

The electricity for our plant comes exclusively from renewable sources and does not compete with the energy transition.

For our fairfuel plant, we only use electricity from wind turbines and solar plants in the area. We chose plants which no longer receive any funding from the Energy Feed-in Act and expand their life span because they would be taken off the grid without our purchase of the electricity due to a lack of economical viability.

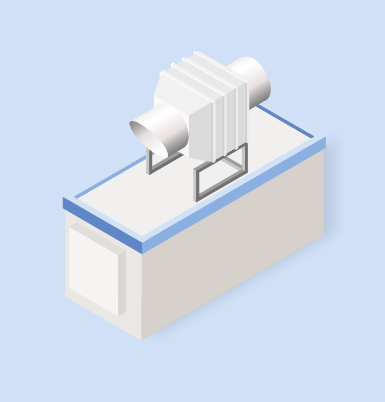

Air Capture Module

Here we extract CO2 directly from the atmosphere.

This process is very energy-intensive.

In order for fuel to be CO2 neutral, CO2 must be extracted from the atmosphere in the same amount as is produced during the flight. One way to do this is direct air capture, which extracts CO2 directly from the atmosphere using filters. Since the concentration of CO2 in the air is low, this process is significantly more energy and raw material intensive than CO2 extraction from a point source. In our system, direct air capture provides around 2.3% of the CO2 required for the process.

Biogas plant

In the biogas plant on site, CO2 is produced in concentrated form as a waste product, which we use as a source for fuel synthesis.

When organic material decomposes in a biogas plant, CO2 is produced in relatively high concentrations in addition to methane, which is normally released into the atmosphere. We use this CO2 from a biogas plant next to our facility for our fairfuel production. The carbon contained in this CO2 was bound in plants in previous years through photosynthesis. It’s use as fuel therefore remains CO2 neutral.

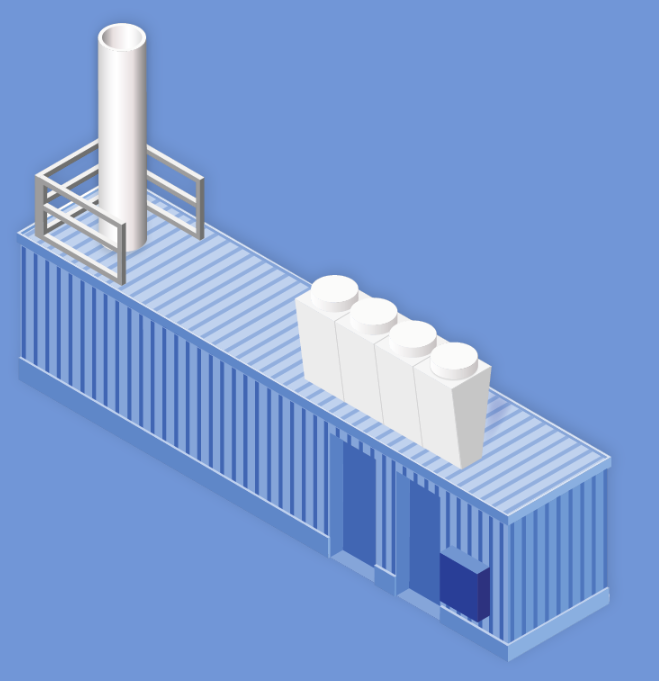

Electrolyzer

In the electrolyzer, hydrogen is produced from water using electricity.

Besides carbon, hydrogen is the second main component in the production of synthetic fuels. Hydrogen is produced from water by electrolysis using electrical energy. Our electrolyzer is based on a membrane that is surrounded by water and uses electricity to separate H2 and O2 (Proton Exchange Membrane – PEM). The plant was built by Siemens Energy.

Fischer-Tropsch Synthesis

Here, carbon and hydrogen are synthesized into hydrocarbons, the final material for the refinery.

In the synthesis plant, carbon dioxide and hydrogen are converted into synthesis gas, which is then used to produce synthetic crude oil, the precursor for atmosfair fairfuel. This is done using the Fischer-Tropsch process, which was developed by the German chemists Franz Fischer and Hans Tropsch in 1925. At temperatures from 150°C to 300°C, long-chain hydrocarbons are produced in the presence of metal catalysts, which are then processed into kerosene in a refinery.

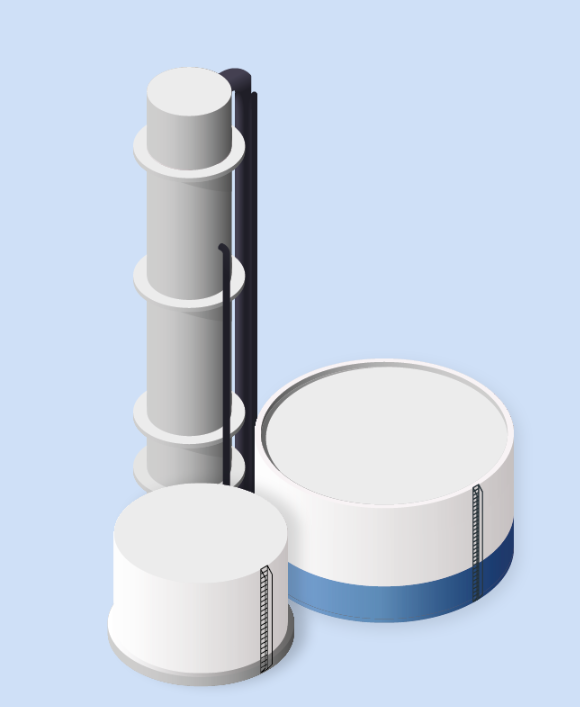

Refinery

Here, the synthetic crude oil is processed into atmosfair fairfuel and supplied to Hamburg Airport, among others. The synthetic crude oil from our production plant in Werlte thus reduces the use of fossil crude oil for fuel production.